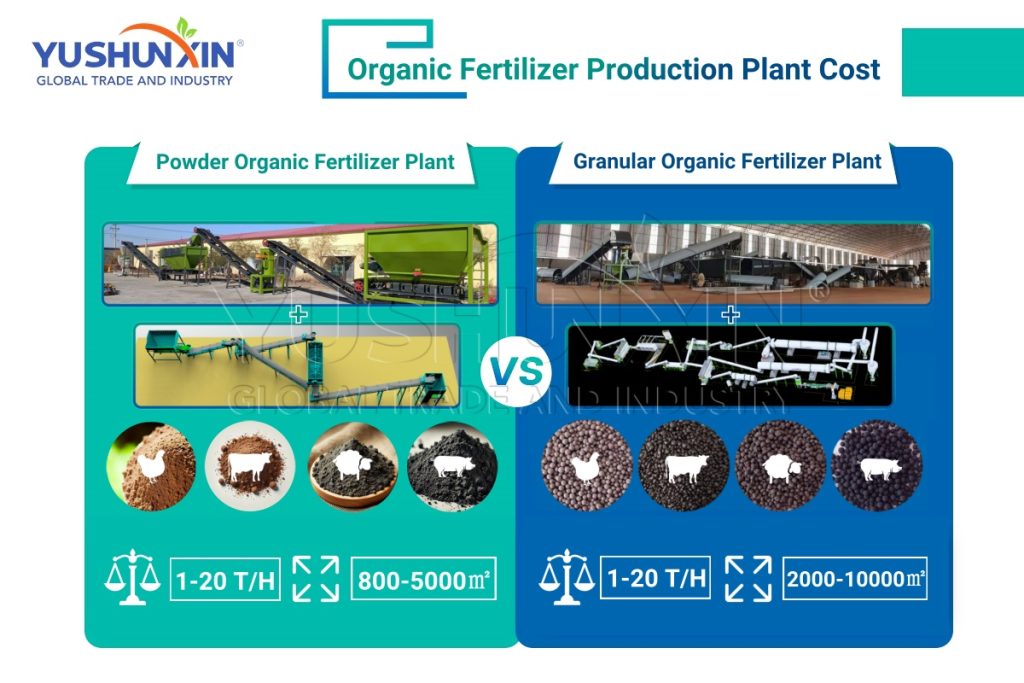

Organic fertilizer particle making machinery influences fertilizer plant cost through equipment selection, line capacity, utility consumption, and installation scope. An investor usually evaluates organic fertilizer plant setup cost by separating the powder procedure from the granulation process, and then matching each step with reliable machinery and controllable operating expense. Moreover, an organic fertilizer production plant cost often changes when a project targets multiple product forms, such as organic fertilizer powder, organic fertilizer granule, or organic fertilizer pellet, because each form requires different preparation, pelletizing, screening, and packing configurations. Therefore, a clear cost map for an organic fertilizer manufacturing plant helps a fertilizer factory control capital risk while improving commercial output quality.

Which raw materials determine organic fertilizer powder production cost and pellet making cost the most?

A project’s raw material plan shapes organic fertilizer powder making cost and organic fertilizer granulation cost because different inputs require different crushing, moisture control, and particle forming difficulty. Common raw materials for organic fertilizer powder production and organic fertilizer pellet production include livestock manure (chicken manure, cow manure, pig manure), composted green waste, crop straw, rice husk, bagasse, mushroom residue, and distillers grains. Some formulas also use oil cake, humic substances, bone meal, or biochar as functional additives, and these materials affect the particle strength and the pelletizing stability. In addition, a raw material with higher fiber content usually increases crushing machine wear, while a raw material with higher moisture content usually increases drying demand and raises fertilizer manufacturing plant cost. As a result, a feasible raw material combination improves granulating continuity, reduces recycle load, and keeps organic fertilizer factory cost within budget.

How do core machines drive organic fertilizer particle making machinery price and fertilizer plant setup cost?

The largest share of organic fertilizer plant cost often comes from the main particle forming machine because the granulator or pelletizer sets capacity, granule shape, and energy consumption. A disc granulator typically suits small to medium organic fertilizer granule production and often provides adjustable tilt angle and stable ball making behavior, while a double roller extrusion granulator often supports low-moisture pellet making and reduces drying pressure in some formulations. A new type organic fertilizer granulator usually targets sticky compost-based formulas and supports continuous granulating with controlled granule size range. Therefore, the selection between granulator models changes both machinery procurement cost and long-term maintenance cost. Moreover, a crushing machine influences total organic fertilizer production plant cost because uniform powder preparation improves granulation yield and lowers return fines. A compost machine, such as a groove type compost turner, also influences the fertilizer plant setup cost when a plant includes fermentation and preparation inside the factory boundary. Each equipment choice affects the organic fertilizer manufacturing plant cost through throughput matching, downtime risk, spare parts consumption, and labor coordination.

What hidden operating expenses increase organic fertilizer production plant cost during granulation and pelletizing?

A complete organic fertilizer granulation line usually generates operating expenses beyond the visible machine price, and these expenses often determine real fertilizer factory cost per ton. Electricity consumption rises when a granulator handles high-fiber powder, and fuel or power consumption rises when a rotary drying machine removes excess moisture after pelletizing or granulating. Wear parts also affect organic fertilizer plant cost because roller skins, bearings, liners, and granulating blades require periodic replacement depending on raw material abrasiveness. Furthermore, dust collection and workshop ventilation influence compliance spending, while moisture control equipment influences product stability during particle making. Packaging also affects fertilizer manufacturing plant cost because a packing machine and bag sealing system require consistent compressed air, bag supply, and calibration service. Consequently, an investor usually includes utilities, consumables, spare parts, and quality inspection in the organic fertilizer plant setup cost model to avoid underestimating total production cost.

Which production line configuration choices optimize fertilizer manufacturing plant cost without lowering pellet quality?

A rational configuration reduces organic fertilizer production plant cost when a plant aligns equipment capacity with targeted powder or granule specifications. A powder line that focuses on organic fertilizer powder manufacturing often needs crushing and screening coordination, while a pellet line that focuses on organic fertilizer pellet production needs stable feeding and controlled granule growth inside the granulator. Many plants add a screening machine to separate qualified particle size and return oversize or fines to re-granulate, and this circulation strategy improves pellet making yield and reduces raw material waste. Some plants add a rotary drying machine when granulation moisture remains high, while other plants prioritize extrusion granulation to reduce drying dependence and manage fertilizer plant cost. Additionally, a batching machine can improve formula consistency and reduce quality fluctuations that create rework and extra recycle. Therefore, a cost-effective organic fertilizer production process depends on product positioning, moisture strategy, and equipment matching rather than on a single expensive machine.

Organic fertilizer particle making machinery cost includes equipment price, installation scope, utilities, wear parts, and line configuration decisions across powder production and granulation production. A disciplined cost plan that connects raw materials, process route, and granulator selection usually delivers a controllable organic fertilizer plant setup cost and a predictable fertilizer manufacturing plant cost over time. A professional fertilizer equipment manufacturer, Yushunxin, can support such planning with compatible machinery options and production line integration. You can visit: https://www.fertilizerproductequipment.com/organic-fertilizer-production-plant-cost/